The field of material science serves as the backbone of modern technological advancements, particularly when it comes to areas operating under extreme conditions, such as nuclear energy and military applications. In these scenarios, materials must endure not only intense pressures but also extreme temperatures and corrosive environments. The quest for materials that are not only resilient but also cost-effective and sustainable has led researchers to investigate the behavior of materials at the atomic level, especially when subjected to stresses that could compromise their integrity.

Scientists at the Lawrence Livermore National Laboratory (LLNL) conducted a fascinating study focusing on zirconium, a metal known for its strength and stability. They compressed single crystal samples of zirconium to astonishing levels, revealing intricate deformation behaviors that challenge previously established norms. Their findings were published in two respected scientific journals, highlighting the significant implications this research holds for understanding material behavior under duress.

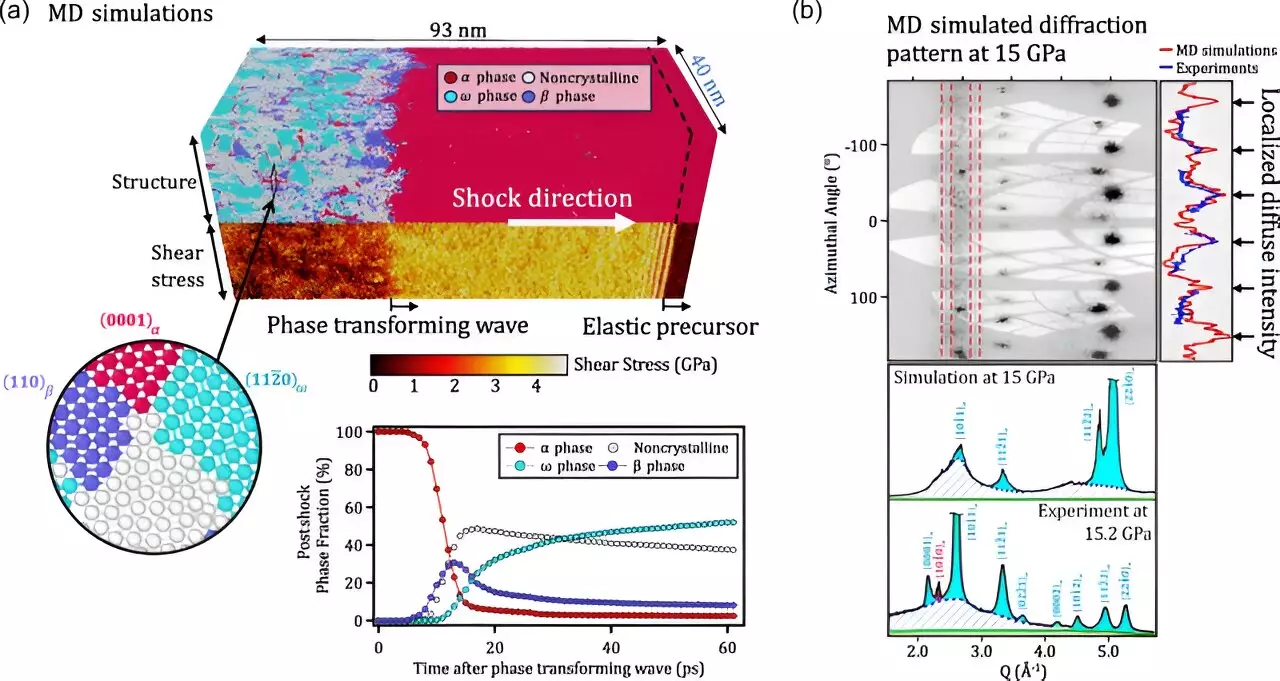

The study illuminated how materials, particularly metals like zirconium, alleviate shear stresses in various complex ways, including dislocation slip and phase transitions. According to lead researcher Saransh Soderlind, it is essential to grasp these microscopic phenomena to predict how materials perform under extreme conditions, paving the way for the design of improved materials.

Complex Deformation Mechanisms

Traditionally, it is understood that metals change their shape plastically when compressed, primarily through defects known as dislocations. However, the LLNL team’s research complicated this narrative significantly. In zirconium’s case, the pressure-induced alterations in the crystal structure added layers of complexity to its behavior. Soderlind stated that accurate mapping of crystallographic planes and deformation directions is crucial for developing predictive models for metallic behavior at high pressures.

Utilizing innovative experimental techniques such as femtosecond in-situ X-ray diffraction, researchers observed zirconium’s behavior compressed to high pressures over brief timescales. The discovery of atomic disorder, a phenomenon not previously recorded in elemental metals, alongside diverse pathways for crystal structure transformation, marked pivotal advancements in the field.

These groundbreaking observations hold vast implications for the nuclear industry and beyond. Zirconium alloys are already essential in nuclear reactors, particularly for fuel rod cladding, owing to their low neutron absorption and high strength. By expanding our understanding of how zirconium and potentially other materials behave under high-stress conditions, the findings present the potential for developing alloys that can endure even more demanding environments.

Furthermore, LLNL scientist Raymond Smith minimized the complexity of these findings, suggesting that such intricate atomic movements may be a commonality among various materials subjected to high pressures. As researchers explore these behaviors further, the potential to enhance material performance and durability across a wide array of applications seems promising.

This ongoing exploration into the behavior of materials like zirconium under extreme pressures not only enhances our fundamental understanding of material science but also propels the development of the next generation of materials. By tapping into these microscopic mechanisms, scientists are poised to innovate materials that meet the rigorous demands of contemporary applications while also ensuring cost efficiency and sustainability for the future.